Climate Strategy and Actions

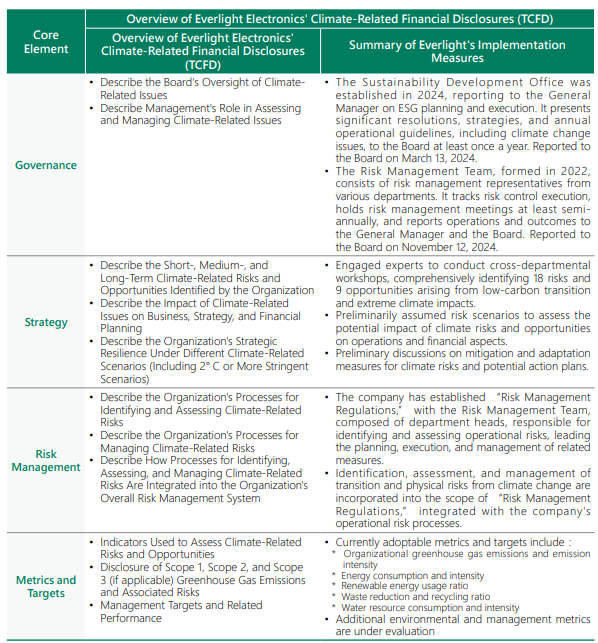

Amid intensifying global warming and the increasing frequency of extreme weather events, all enterprises face unprecedented challenges and opportunities. Stakeholders are placing greater emphasis on the effectiveness and transparency of corporate climate strategies and actions. Everlight closely monitors global climate change trends and international response directions. In doing so, the company adopts the framework recommended by the Task Force on Climate-related Financial Disclosures (TCFD), established by the Financial Stability Board (FSB), to assess the risks and opportunities associated with climate change. Through this framework, Everlight evaluates potential adaptation and mitigation measures, as well as their financial impacts. The company is actively planning to enhance the clarity and completeness of its disclosures in the near future, in order to gain the full support of customers, investors, and publicsector stakeholders for its climate strategy initiatives.

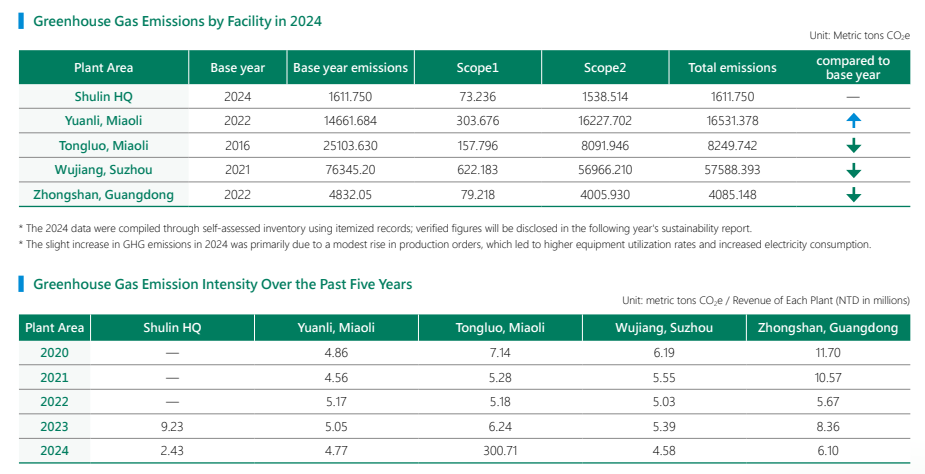

Greenhouse Gas Emissions Management

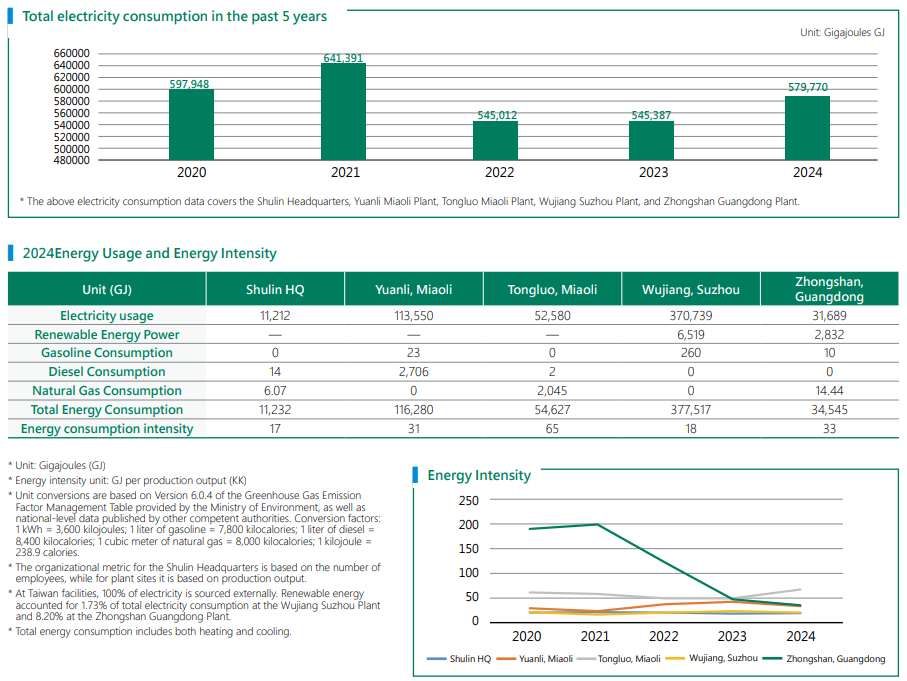

Energy Management

Waste Management

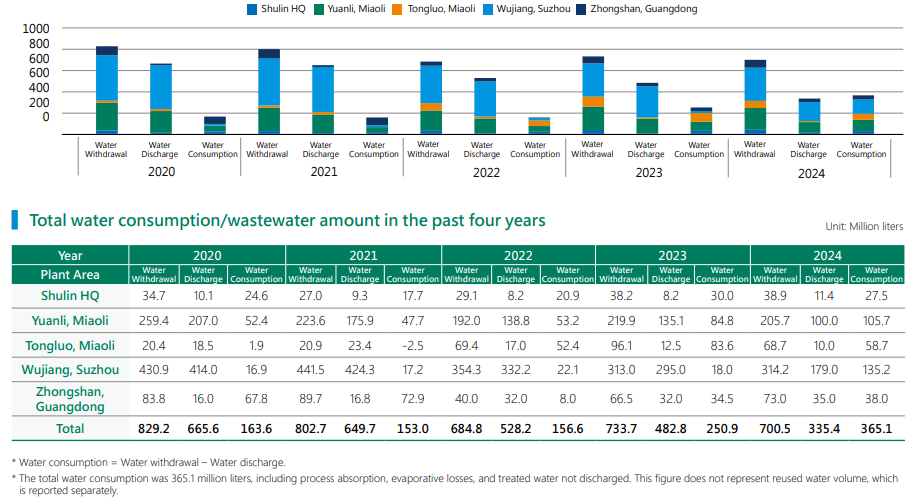

In 2024, Everlight’s total water withdrawal reached 700.5 million liters, representing a reduction of approximately 4.5% compared to 733.7 million liters in 2023. This decline demonstrates the Company’s ongoing efforts and tangible progress in promoting water conservation and improving water use efficiency.

The primary sources of water include industrial tap water and local municipal supply systems, and none of Everlight’s sites are located in water-stressed areas. To strengthen water resource management, each operating site has implemented several key measures, including improved water-saving designs in production processes, leak detection and control in pipeline systems, and the optimization of cooling and cleaning procedures to reduce non-essential water use. In addition, the Company continues to promote water-saving behavior through employee education and awareness programs to enhance day-to-day water use efficiency. Notably, in 2024, the Wujiang Suzhou Plant significantly reduced its wastewater discharge by introducing a recycling system for process wastewater, allowing treated water to be reused within operations.

For more details, please see the Sustainability Report>>https://en.everlight.com/csr11/